SEAMLESS TRANSITION TO 200MM PROCESSING

Ready to simplify your transition from 150mm to 200mm wafer processing?

Delaying your transition to 200mm wafer processing could lead to

increased operational costs, reduced efficiency, and significant competitive

disadvantage in a rapidly evolving semiconductor industry.

Maximize Your Fab's Potential

with the Analogee 200D

The Analogege 200D System is engineered to eliminate the bottlenecks of 200mm transitions. By combining precision automation with a high-speed SCARA interface, we help you achieve faster cycles and higher yields without the typical growing pains.

-

Dual-Bridge Versatility: Native 150mm and 200mm compatibility for a risk-free transition.

-

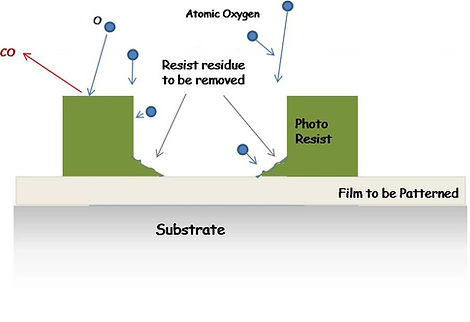

Precision Surface Prep: Advanced descum and controlled resist removal with water cooled patten for superior quality.

-

High throughput: Integrated SCARA robotics minimize wafer handling time.

-

Maximum Yield, Minimum Space: A compact, space-saving footprint designed for high-density cleanrooms.

-

Industry-Leading ROI: Engineered for the lowest total cost of ownership (TCO) in its class.

APPLICATION NOTES

Access our technical notes and research papers designed to help engineers and professionals better understand semiconductor processing. Download and review our detailed documents anytime.